A Gemba Walk is a Japanese term, which can be translated as “Where Things Happen”, to describe a field or workshop tour conducted by an operational team leader. Gemba Walks, not to be confused with 5S audits, are part of the lean philosophy and are central to managerial actions on the shop floor, but above all they make it possible to appreciate what is really happening, to identify best practices and to escalate issues encountered by operational staff.

However, when the health situation meant remote work became widespread, this traditionally paper-based system proved to have its limits. Today, managers are faced with a constraint: carrying out field audits allows them to keep in touch with the staff on the shopfloor, but reporting information on paper is not practical and wastes too much of their time day-to-day.

The question we will try to answer in this article is: how to digitalize Gemba Walks while maintaining contact with staff on the ground?

What are Gemba Walks?

A Gemba Walk can have different forms or routes, and can be called a “field tour”, or a “shopfloor tour”… There are several objectives for the manager, but the first is to better understand and analyze the process flow and to have a comprehensive grasp of the staff’s day-to-day activity.

Gemba Walks is useful to the manager in many ways, such as:

- Taking a step back from staff activity to better detect what cannot be seen when the manager is not in the field;

- Detecting departures from the fundamental rules and, for example, reminding people of the importance of safety rules on the production lines;

- Identifying best practices that add value;

- Identifying any operational issues;

- Empowering staff and developing their self-reliance.

Gemba Walks are crucial to ensuring that production runs smoothly. These field tours always end with a time of sharing observations between the manager and the staff concerned.

What are the benefits of digitalizing field audits?

As paper-based performance rituals have shown their limits, having them in digital format is essential to better understanding the daily reality of shopfloor staff, and therefore provides many benefits for team managers:

- Collaboration and communication are simplified: with a simple and intuitive digital collaboration solution, the different people involved in a project have access to the same information whenever they wish and can therefore share the information more easily if necessary.

- Data is more accessible thanks to historization: with the data history, project stakeholders have access to previous actions, problems encountered, identified causes, etc. Action plans can therefore be adjusted on the fly, which facilitates decision-making. Archiving audit reports in digital format can be very valuable for activities that are subject to frequent regulatory audits (agri-food, aeronautics, etc.)

- Staff responsiveness and commitment are increased: notifications about actions enable staff to react faster in case of detected anomalies, such as a spike in defects for example. As a knock-on effect, staff members become more motivated and invested in projects.

The digitalization of rituals and processes (such as Gemba walks, 5S audits, performance meetings) allows your employees to better manage their daily work schedule, and to optimize each task, which significantly increases their level of autonomy in problem-solving.

Digitalizing Gemba Walks with Fabriq? What are the benefits?

Digital solutions are proven to be key to performance management and productivity improvement. But how do you choose the tool that will enable you to reap all the benefits of digitalization and really see results?

It’s essential to select an easy-to-use tool that will be accessible to staff on the ground. An easy-to-learn tool allows operators to feel at ease and take features on board faster. Let’s take a look at the essential selection criteria.

Shopfloor problem reporting during your Gemba Walks

Using our tool you can raise a problem via a ticket, mid-routine. This means you can report a problem in the app without having to interrupt your Gemba walk.

Also, creating a dependency between the ticket and the routine, it is easier to navigate between them. The ticket will be linked to the specific Gemba Walk routine.

The employees concerned naturally take part in the problem-solving process that is initiated. They also have access to past actions on this topic and the responses during the routine.

Communication on your routines

You can create a communication containing the elements of the routine you have carried out and share it beyond the team. The goal is to share the result of the routine with other teams: comparing scores between two similar shop floors, or sharing a comment or a security issue, for example. In your communication, you can download the routine in pdf format and give all the site’s staff access to information about it: title, date, completion percentage, author…

Capitalization on routine data

Any tickets created from a routine can be archived, like any other ticket. Archiving these tickets means you can find them at any time if you come up against a similar problem.

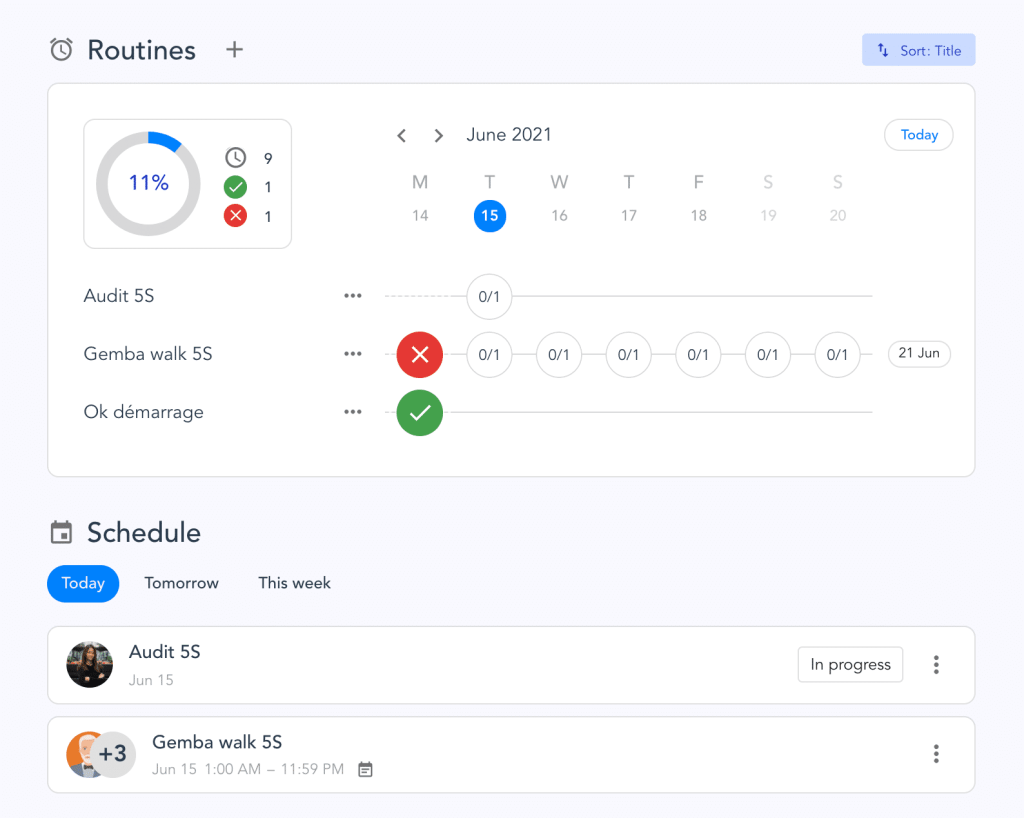

Logging routine data makes it possible to create process indicators (kpi) in the tool, with daily dashboards displaying the status, progress or score of field audits and visits.

You can also download the history of responses to routines performed by your teams in order to carry out custom analyses.

Connecting your routines to your SIMs

There is another major benefit to digitalizing Gemba walks, audits and field visits: you can connect them to your dashboards and visual management for use in your Short Interval Meetings (SIM). Whether it is corrective action to be taken as a result of non-compliance identified during a quality routine, or a safety risk that staff should be made aware of, the information can be easily consolidated and prioritized during your SIMs so that any performance gaps can be addressed as quickly as possible.

Visualization of routine indicators (score, status, % completion) also allows you to see at a glance any performance gaps or Andon-type anomalies and provide a quick response via an action plan or by escalating the information to the next level.