Picture this- you’re at the quality control station for a pharmaceutical packaging unit and notice a printing error on the label. You’ll need to send the entire lot back to be redone. Though you will probably salvage the product itself, it’ll take considerably more time and effort. No one likes a re-do. That’s why you need to take a Right First Time or First Time Right approach. Keep reading to understand this concept, learn how to calculate your RFT score and what you can do to improve it.

What is Right First Time?

Right First Time (RFT) and First Time Right (FTR) are interchangeable terms. It is a manufacturing principle with origins in the Six Sigma methodology. It is also an important Key Performance Metric

(KPI). A high RFT indicates low waste and vice versa.

Definition of Right First Time

The term is quite self-explanatory. Right First Time refers to ensuring a product is manufactured or a procedure is performed correctly from the very first time onwards. The goal here is to minimize rework and waste thereby optimizing efficiency.

That said, RFT does not insist on perfection. Rather, it focuses on continuous improvement and putting the right systems in place.

How do you calculate your RFT score?

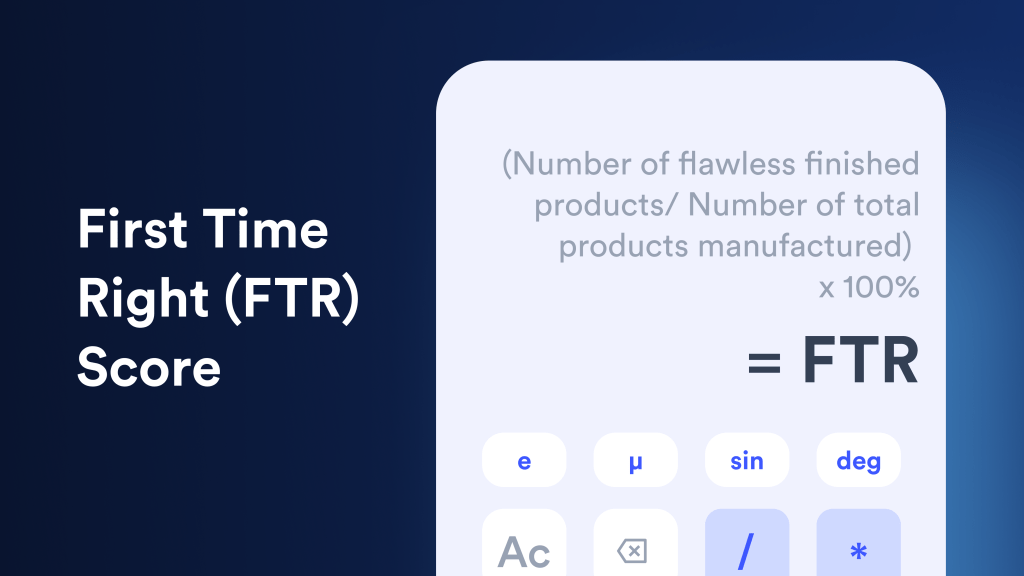

As a metric, your RFT score reflects the percentage of finished products produced correctly on the first attempt. You can calculate this score as:

RFT/ FTR = number of flawless finished products/ number of total products manufactured x 100

You can calculate this score at the end of every manufacturing stage as well as when an order is ready for dispatch. The latter is an average score. The formula here is:

RFT/FTR = (RFT at stage 1 + RFT at stage 2 + RFT at stage 3…..)/ number of stages

Here’s an example.

Let’s say of 60,000 products in a batch, 54,000 passed quality inspection.

RFT=54000/60000*100 = 90%

If this was stage 1 of production, stages 2 and 3 had an RFT score of 92% and 86%.

The total RFT score is: 90% + 92% + 86%/3 = 89.3%

Why do you need to improve your Right First Time score?

Achieving a 100% RFT score is almost impossible. The Six Sigma concept itself allows for slight inefficiency. Hence, the goal of improving RFT scores is to bring it as close to 100% as possible.

A low RFT score indicates inefficient processes that may limit your profit margins. After all, every re-do takes additional resources without increasing the finished product’s value.

Improving your RFT score reduces waste and makes processes more efficient. Reducing the number of do-overs lets you cut down on the defect rate as well as increase profit margins. It also increases the overall product quality and, in turn, increases customer satisfaction.

Improving RFT scores can also affect employee morale. The people working your machines have the satisfaction of knowing that they’re working on fresh orders instead of reworks. Hence, they feel more satisfied with their output at the end of the day. And, as every factory manager will agree, a happy workforce is a more productive workforce.

How to improve your Right First Time score?

Improving your RFT score may involve making changes to design, workflows, training and so on. DMAIC (Define, Measure, Analyze, Improve, and Control) is a good way to start. It allows you to take a systematic data-driven approach to identify opportunities for improvement and make impactful changes. The key steps here are:

Step 1 – Define the Problem

Manufacturing units must calculate RFT at every stage of production. Take a closer look at the stage with the lowest RFT to identify where the problem lies. It may be a bottleneck in terms of workflow or insufficient raw materials. Or a machine may be malfunctioning.

Step 2 – Measure the Extent of the Problem

Measure how this problem impacts your plant’s overall efficiency. This involves looking deeper into the amount of wasted material, time spent on re-work, products that cannot be sold and so on.

Step 3 – Analyse the Root Cause

Re-doing a part of the manufacturing process may fix the immediate problem but there’s always the risk of it reoccurring. The only way to avoid this is by addressing the root cause of the problem. The 5 Whys and Fishbone diagrams are effective tools for root cause analysis.

Let’s go back to the situation mentioned at the beginning of this article.

Why did the wrong buttons get put onto the shirt? Were the wrong buttons ordered or did they get exchanged with another set in the stock room?

Step 4 – Improve the Processes

Once you have identified the root cause, brainstorm possible solutions and test them out on a pilot project. Small changes can have a big impact. For example, rearranging the stock room and using visual cues could keep your team from picking the wrong materials.

Step 5 – Control and Monitor Performance

Monitoring the effect of a change lets you assess its impact. Some changes may not have the intended effect and you may need to try something different. However, if changing a process improves the RFT score, it can be implemented as a standardized process across the factory.

How to track your Right First Time score with a digital tool

Improving First Time Right Six Sigma scores requires consistent efforts. Having the right tools makes it easier. Digital management solutions like Fabriq can play a significant role at each stage of the DMAIC process.

For example, let’s look at the first stage of the DMAIC process to improve RFT. Your team can use customized forms and visual checklists when conducting performance audits. Further, they can report findings with field data.

Performance metrics can then be easily transformed into visual graphics. This makes them easier to understand and compare. The platform also makes data shareable so everyone included in your daily huddles is on the same page. Fabriq also supports tracking the impact of proposed changes to accelerate the execution of continuous improvement actions.

Summing It Up

It’s been rightly said, “It’s always cheaper to do the job right the first time”. Even with a low RFT score, you might get your products to market and have a satisfied customer base. But, reworking products may eat into your resources and limit profit margins.

Your RFT score may not reach 100%. Yet, implementing and tracking the impact of small changes to your processes can help significantly improve it. This not only increases your profit margins but also has an impact on employee and customer satisfaction rates. Visual management solutions like Fabriq make the process smoother. It can help you take a more structured approach to this process and make impactful change. Ready to know more – reach out today.

Right First Time: FAQ

What is Right First Time in manufacturing?

Right First Time (RFT), also known as First Time Right (FTR), is a manufacturing principle rooted in the Six Sigma methodology. It refers to producing a product or completing a process correctly on the very first attempt—without needing rework. A high RFT score indicates efficient operations and minimal waste.

How do you calculate the Right First Time (RFT) score?

Your RFT score measures the percentage of products made correctly on the first try.

The formula is:

RFT = (Number of flawless finished products ÷ Total products manufactured) × 100

You can also calculate an average RFT across multiple stages of production using:

RFT = (RFT at Stage 1 + RFT at Stage 2 + …) ÷ Number of stages

Why is it important to improve your RFT score?

Improving your RFT score reduces waste, rework, and inefficiencies, helping you increase profit margins and product quality. It also boosts customer satisfaction and employee morale, since workers spend less time fixing issues and more time producing new, quality products.

What are the best ways to improve Right First Time performance?

To improve your RFT score, manufacturers can use the DMAIC process:

-

Define: Identify where RFT is lowest.

-

Measure: Quantify the problem’s impact on waste and efficiency.

-

Analyze: Find the root cause using tools like 5 Whys or Fishbone diagrams.

-

Improve: Test and implement corrective actions.

-

Control: Monitor and standardize effective solutions.

How can digital tools like fabriq help track and improve RFT scores?

Digital platforms like fabriq simplify tracking and improving RFT performance. Teams can use visual checklists and data forms to collect real-time performance data, generate visual reports, and share insights across teams. Fabriq also helps monitor the results of process changes, accelerating continuous improvement initiatives.