In manufacturing environments, operational efficiency isn’t just a goal, it’s a necessity. Recurring problems like equipment breakdowns, product flaws, or safety issues can hurt productivity and profits. It is important to address them quickly and effectively. That’s where root cause analysis (RCA) tools like the 5 Whys come in. This simple yet powerful method helps manufacturers go beyond surface-level fixes to uncover the real reason a problem is happening and address it for good.

Whether you’re implementing a broader lean strategy, QRQC, or just want a reliable method for continuous improvement, the 5 Whys technique is a great place to start.

What Is the 5 Whys Problem Solving Method?

The 5 Whys problem solving is a root cause analysis technique used to systematically identify the underlying cause of operational issues. They do this by asking “why?” five times, or as many times as needed to get to the root cause.

The 5 Whys originated from the Toyota Production System. It is one of the most accessible and effective problem-solving tools used in lean manufacturing. It relies on logical reasoning rather than complex data analysis, making it easy to use on the shop floor.

The 5 whys problem solving method is designed to identify the root cause, not just the symptoms. It can be used alone or as part of a broader problem-solving framework.

Why Use the 5 Whys in Manufacturing Operations?

Manufacturing operations are full of moving parts, and even small issues can snowball into bigger problems if left unaddressed. The 5 Whys method is ideal for this environment because it encourages fast, focused investigation.

Here are five reasons manufacturers might use the 5 Whys:

- Speed: It can be completed quickly, often in under 30 minutes.

- Simplicity: No need for special training or software.

- Team Alignment: Encourages cross-functional collaboration.

- Continuous Improvement: Supports lean, kaizen, and QRQC efforts.

- Actionable Outcomes: Leads directly to corrective actions that prevent recurrence.

Use cases range from addressing line stoppages and supply chain delays to improving quality and safety outcomes.

Conduct a 5 Whys Analysis: A Step-by-Step Guide

To get the most out of the 5 Whys method, structure and consistency are key. Here’s how to run a successful 5 Whys analysis on the shop floor:

1. Define the Problem Clearly

Start with a specific, observable problem. Avoid vague or generalized statements.

Bad: “The machine keeps breaking.”

Good: “The machine stopped during the morning shift due to a misaligned sensor.”

2. Assemble the Right Team

Include people who are directly involved with the process or equipment in question. Operators, maintenance technicians, and line supervisors often have the best insights.

3. Ask “Why?” and Keep Going

Use each answer as the starting point for the next why. Here is an example:

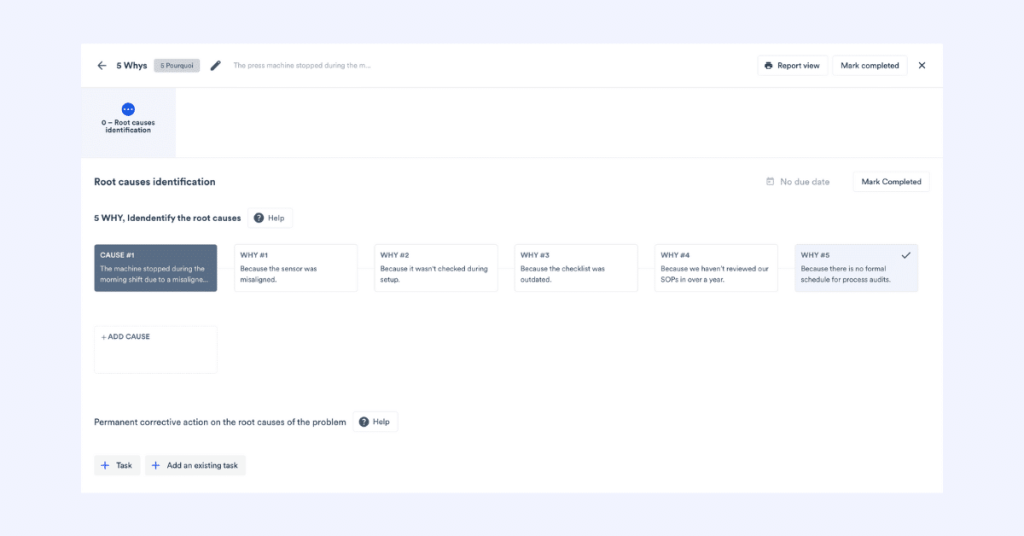

- Why 1: Why did the machine stop? Because the sensor was misaligned.

- Why 2: Why was the sensor misaligned? Because it wasn’t checked during setup.

- Why 3: Why wasn’t it checked during setup? Because the setup checklist was outdated.

- Why 4: Why was the checklist outdated? Because we haven’t reviewed our SOPs in over a year.

- Why 5: Why haven’t we reviewed SOPs? Because there is no formal schedule for process audits.

4. Identify the Root Cause

When you reach a cause that, if fixed, would prevent the issue from recurring, you’ve likely found the root cause. It’s not always the fifth why. Sometimes it takes three whys, sometimes it takes seven.

5. Take Corrective Action

Implement changes that address the root cause directly. In this case: Create and enforce a regular SOP review schedule.

6. Document the Analysis

Use a template or digital tool to capture the process, participants, answers, and next steps. This helps with follow-up and accountability.

Example of a 5 Whys Analysis in fabriq

5 Tips to Build a Root Cause Culture on the Shop Floor

The 5 Whys is only as effective as the culture supporting it. Here are five tips for embedding root cause thinking in your manufacturing organization:

- Make It Part of Daily Routines: Integrate 5 Whys analysis into QRQC routines, Gemba walks, and morning meetings.

- Train Teams on How to Ask the Right Questions: Problem-solving isn’t just about asking why, it’s about asking the right why. Provide training or job aids to guide the process.

- Encourage a No-Blame Environment: Psychological safety is key. Focus on fixing processes, not blaming individuals.

- Use Digital Tools to Track and Share Analyses: A digital problem-solving platform like fabriq helps standardize the 5 Whys method. It promotes sharing knowledge and tracks recurring issues over time.

- Celebrate Successes: Highlight wins where root cause analysis led to real improvement such as reduced downtime, fewer defects, improved safety, etc.

How 5 Whys Problem Solving Drives Continuous Improvement

The 5 Whys method is a low-cost, high-impact tool that can transform how your team approaches problem solving. When used consistently, it helps manufacturers reduce waste, prevent downtime, and foster a culture of continuous improvement.

Looking to empower your teams to solve problems in real time? fabriq’s digital platform helps manufacturers organize and document root cause analyses, like the 5 Whys. It also fits into your daily routines and key performance indicators (KPIs).

Request a demo today to see how fabriq supports real-time problem solving on the shop floor.