Operating a manufacturing unit efficiently requires tracking work progress, spotting and addressing issues proactively, and improving overall factory performance continuously. SQDIP, a powerful visual management solution, can help in this regard. You can use it to monitor vital metrics like safety, quality, delivery, inventory, and productivity, as well as improve the same.

SQDIP boards enable you to capture and represent important data in an easily comprehensible manner, delve into shop floor performance, and utilize resources better. Aligning with budgets and timelines becomes simpler and collaboration and operational efficiency also improve.

This article explores SQDIP in detail and sheds light on the benefits of digital boards as well as the implementation process.

What is SQDIP?

Here’s a breakdown of the acronym, to help you appreciate the possibilities of this daily management system:

- Safety

This particular metric tracks accidents and major near-misses that happen at the worksite. It gauges the safety performance of your factory, delves into the effectiveness of current practices, and flags improvement areas. The metric also tracks safety training, employees’ roles in preventing incidents, and the time taken for injured workers to resume duties. You can also track regulatory compliance this way and avoid penalties and investigations.

- Quality

This aspect of SQDIP boards focuses on maintaining the value chain’s quality at every stage. Strict systems for quality control are implemented throughout the production process, ensuring employee involvement and compliance. You get to identify defects in raw materials as well as finished goods. It also becomes easy to track product test fails, items that don’t conform to standards, and rework activities. You can even gauge the customer’s quality perception of end products and ensure constant improvement backed by real-time data.

- Delivery

The delivery aspect of the SQDIP performance management tool ensures smooth logistics, so that all deliveries happen on time, whether to end consumers or from suppliers. You can closely monitor warehouse operations and the flow of inventory as well as maintain a count of delays. By analyzing the movement of stocks, it becomes easier to predict future trends.

- Inventory

With the inventory metric, you can analyze stock data and maintain optimal levels at all times while minimizing waste. Be it equipment, raw materials, or finished goods, it will be easy to make sure you can deliver what’s promised. You can also derive valuable insights into inventory turnover and stock handling to make accurate predictions about future inventory demand.

- Productivity

This metric helps you standardize practices, engage employees, utilize resources efficiently, and streamline operations to create and nurture a continuous improvement culture. You can keep an eye on employee training, measure professional skills, develop leadership, and improve the overall organizational culture. Ultimately, this will lead to greater factory performance and consistent, optimal output.

Also note that many manufacturers use SQCDP boards, which are just like the SQDIP ones with one difference. Instead of inventory, cost is used as a key parameter. And it refers to the cost of production – encompassing material, labor, utilities, wages, and more. The aim is to control costs for maximum profitability.

Why Digital SQDIP Boards Drive Better Production Results

Physical SQDIP or SQCDP boards are essentially whiteboards that can be set up in various areas of production. However, maintaining them can take up substantial time and effort. Also, such conventional boards have limited capabilities when it comes to storing and displaying data.

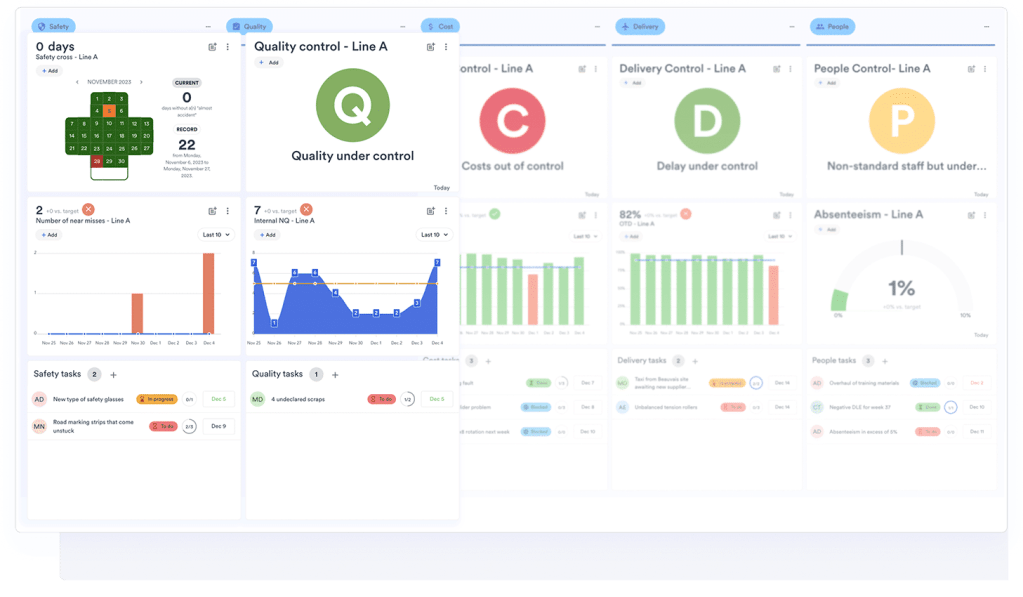

However, digital SQDIP boards facilitate:

- Collection and analysis of real-time data to enable timely identification and correction of anomalies

- Automation of key metrics as well as report generation

- Easy understanding of information for all through a visual, interactive process

- Glitch-free interaction and productive collaboration among multiple teams and stakeholders

- Sharing of insights across team members, even in remote setups too

- Hassle-free access to performance-related past data

As an advanced shop floor management tool, digital SQDIP or SQCDP boards drive better production by improving:

- Productivity

By focusing clearly on key metrics, your teams can prioritize tasks better and resolve requirements and issues faster.

- Work Environment

Regular discussions, an improved sense of ownership, and transparent performance tracking help team members to communicate and collaborate smoothly.

- Quality

Since quality-related metrics are visible clearly and to everyone, spotting problems or bottlenecks early is possible. Your teams can also undertake necessary actions to correct the same this way.

- Employee Engagement

With digital SQDIP boards, employees can track their responsibilities and performance easily and in real time. This will instill ownership in them and encourage employees to update actions or results proactively.

- Safety Awareness

Safety incident tracking can make factory workers and supervisors more aware of potential risks and adopt practices to prevent them. And fewer incidents mean less downtime or operational interruption.

- Goal Alignment

Key indicators are defined in advance to track shop floor performance. This means you can align every operation or function with your company’s strategic objectives.

- Process Refinement

By using digital SQDIP boards, you can study data trends over time and obtain insights that will help you make better decisions in the future. Everyone will feel the drive to tackle problems before they emerge, collaborate more efficiently, and improve wherever there is room to do so.

How to Start Using SQDIP on Your Shop Floor

While implementing a visual management tool like SQDIP can depend on your specific industry or company type, here are some common steps to consider:

- Identify the essential performance indicators or operation-related metrics first, so you have a solid foundation in place.

- Set up digital SQDIP boards in key locations to track shop floor performance in real time.

- Hold daily meetings or huddles and leverage the SQDIP boards to review performance. You can spot bumps or bottlenecks during these sessions, communicate with multiple teams transparently, and get the issues resolved quickly. Escalate serious problems to higher management if required.

- Make sure the SQDIP boards are properly structured and use charts, color coding, and action logs to offer quick insights.

- Analyze patterns, trends, and any issues that might be occurring repeatedly. Leverage data-powered understandings to carry out corrective measures and promote a constant-improvement culture.

- Integrate SQDIP boards with manufacturing execution systems or enterprise resource planning tools to achieve operational excellence faster.

How Digital Visual Management Boosts Factory Performance

SQDIP, as a cutting-edge performance management framework, helps you monitor and manage all vital metrics effortlessly. From workplace safety, quality of the value chain, and logistics to inventory and shop floor productivity, you can improve it all with data-backed insights.

Digital, customizable boards are especially helpful as they automate real-time data collection and analysis, enable timely troubleshooting, boost collaboration, and display historical trends. Most importantly, they foster a continuous-improvement environment that optimizes output over time.

fabriq simplifies the implementation and usage of SQDIP or SQCDP boards as well, from defining dashboard standards to scaling operational excellence. For performance meetings, you can also make the most of various dynamic interfaces. And besides saving precious time for everyone, these dashboards are easy to view on mobile devices.

Book a free demo of fabriq’s digital SQDIP boards and see how visual management can drive real impact.