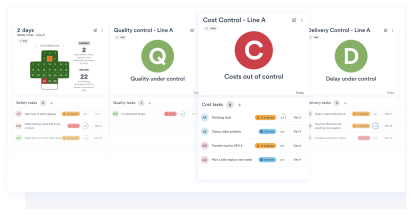

Make it easier to detect and analyze performance gaps in your workshop with our dashboard

Your teams can report any kind of non-conformance, whether operational issues or improvement ideas, by enriching field data with photos, videos and more. Improve detection of non-conformance with our digital solution.

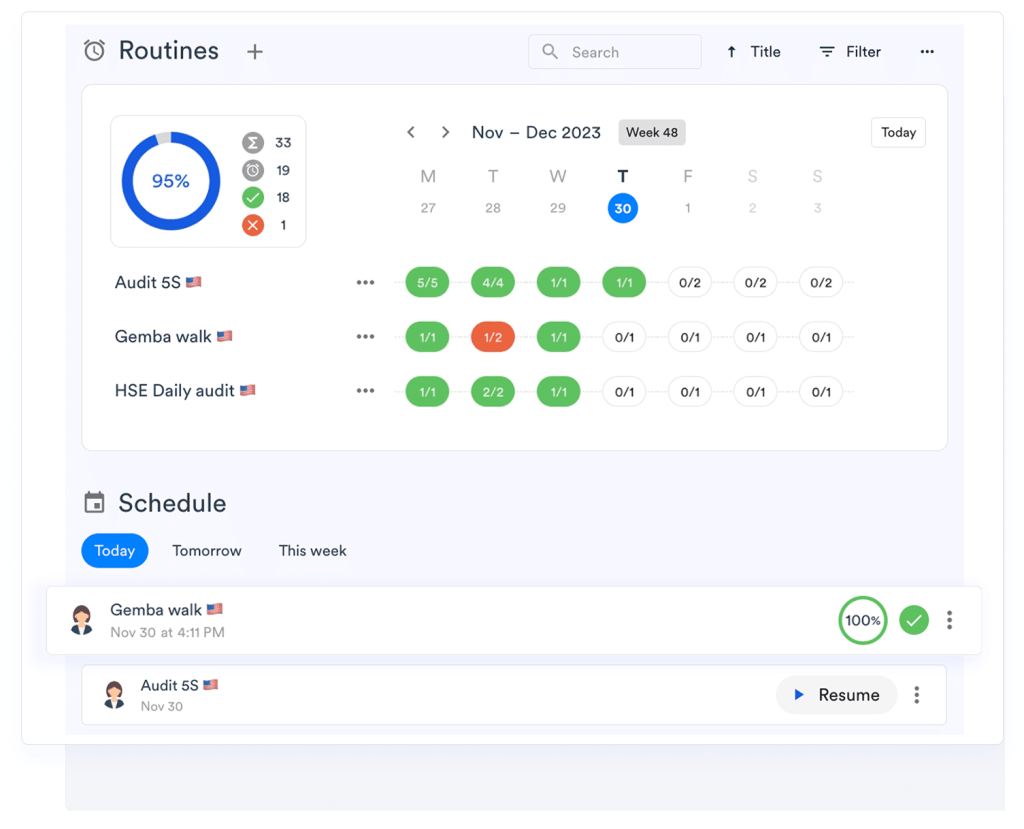

Step 1: Create, schedule, and assign your audits and plant tour

Intuitively create customized forms and schedule them over time, sharing them with your teams and assigning them to responsible individuals. Clearly visualize the checklists to be completed and automatically notify responsible parties in advance.

Clear and intuitive scheduling

Elimination of paper-based support

Elimination of errors during data re-entry

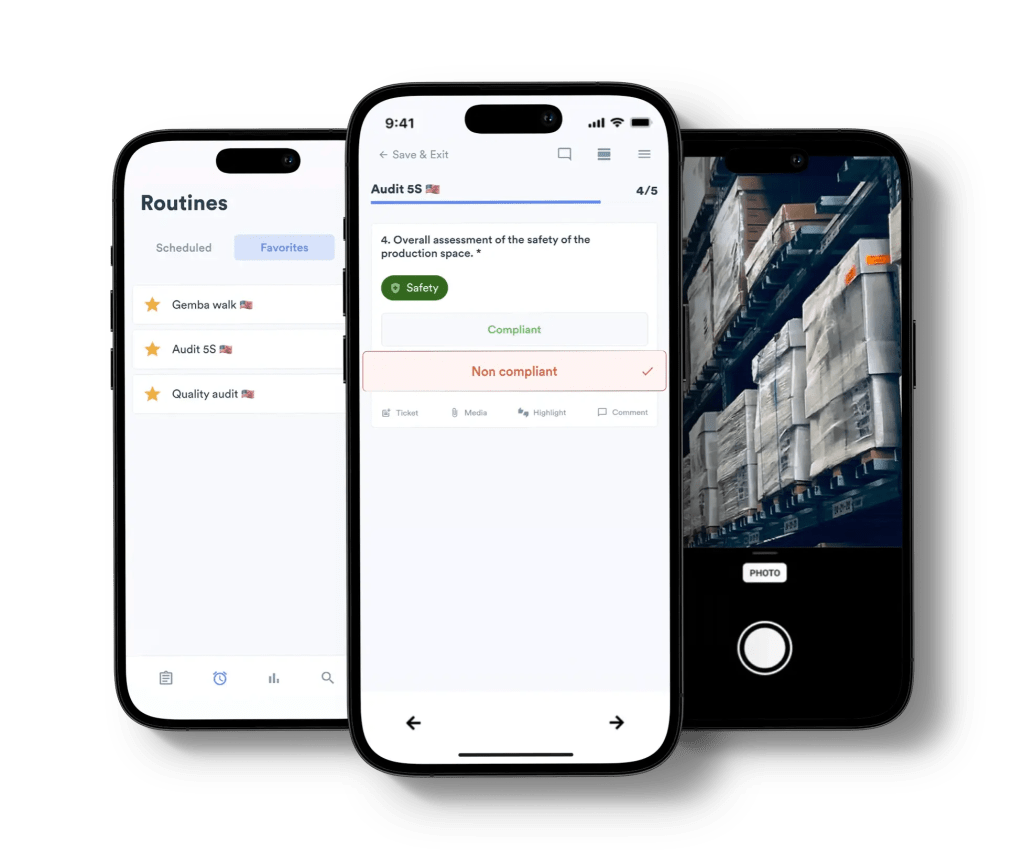

Step 2: Perform your audits and plant tour on mobile

Enhance your flexibility with our mobile application, enabling supervisors to carry out field tours and report non-conformities, even without an internet connection. They will be guided through each step and will automatically access the right information at the right time.

Offline access to Routines & Checklists

Access to necessary documentation

Time savings and elimination of data re-entry

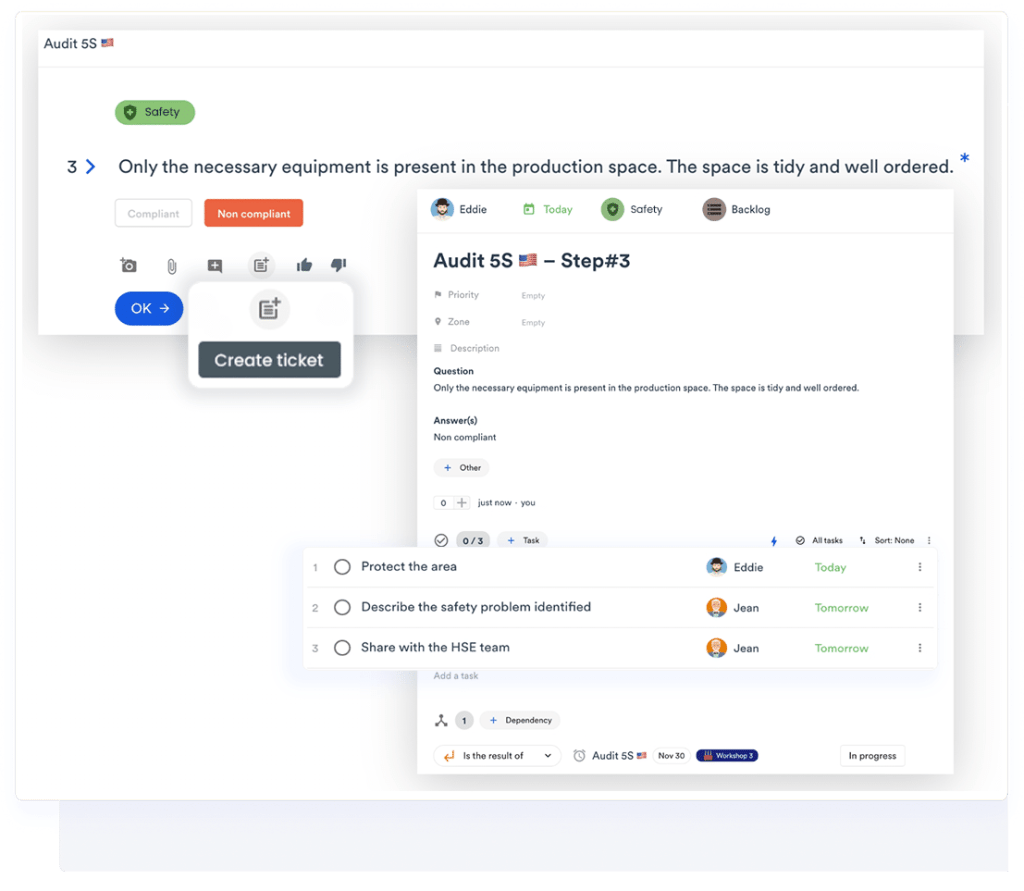

Step 3: Detect and enhance non-conformance

Report all types of non-conformance from standards, operational issues, or improvement ideas enriched with on-site data (photos, videos, etc.). These data allow you to provide maximum context to the deviation, making its resolution easier.

Capture photos and videos to simplify issue reporting

Detection of discrepancies

Time savings and elimination of data re-entry

Step 4: Report problems and create tickets from your mobile application

Eliminate the need to manually copy issues and data by easily sharing them with your teams. Problem reporting and escalation are simplified and occur in real-time. Assign teams to your tickets and escalate problems to the appropriate level.

Real-time synchronization of problem reporting

Multi-platform synchronization

Improved team collaboration

Step 5: Make the right decisions with analyses

Analyze your plant tour to enhance your decision-making. You can track adherence to your schedule and your process with checklist completion rate analyses.

Audits completion tracking

Routine score tracking

Highlighting recurring issues

What our customers say

Over 12,000 users use fabriq daily to more effectively solve operational issues as a team. Discover their feedback!

“With the introduction of Fabriq, we’ve observed numerous benefits, especially in preparing our daily routines and also in addressing medium and long-term actions. Therefore, thanks to Fabriq, we’ve been able to prevent line stoppages due to the speed and processing of data.”

Benefits of Fabriq for:

The benefits of Fabriq for a site manager

“We quickly realized that with Fabriq, there was a fairly comprehensive tool that went beyond what we were looking for. The big advantage is that it’s really intuitive. The communication part, I use it a lot; it reduces the need for emails. We really have both downward and upward communication. Especially the indicators, for me, it allows me to see where we stand.”

Frédéric Sollic, Site manager

The benefits of Fabriq for a Continuous Improvement Manager

“Today, having Fabriq at Nicomatic is evident. The implementation of Fabriq has already allowed us, in a one-hour meeting, to reduce meeting time. And today, we know how precious time is. In three words for me, Fabriq is: trust, responsiveness, and interaction.”

Davy Curier, Continuous Improvement Manager

The benefits of Fabriq for a Digital Transformation Manager

“Digitization with Fabriq has not only revitalized meetings, increased problem-solving responsiveness, but also provided access to data that was once manual, and strengthened the appeal for the younger generations.”

Anne-Delphine Beaulieu, VP Digital transformation

The benefits of Fabriq for a Quality Manager

“We have a solution that is highly intuitive, which today, with new technologies, is within the reach of all our operators and managers. It’s also easy to implement, with no software installation required. So, we have something that is very agile in terms of installation and also in the maintainability of this solution, as well as the updates offered by Fabriq.”

Pascal Trilles, Continuous Improvement and Quality Manager

The benefits of Fabriq for a Production Manager

“Transferring our PDCA (Plan-Do-Check-Act) through Fabriq allows us to have a centralized and cross-functional tool that communicates with other departments and provides an overall view of actions related to specific topics.”

Florent Gaudoin, Production Manager

Our latest articles

Manufacturing Visibility: What It Is and Why It Matters

Lean Transformation: A Guide for Manufacturing Leaders

Skills Matrix: Workforce Agility & Knowledge Sharing