Thanks to Fabriq, Aspen Pharma improves responsiveness and operational efficiency

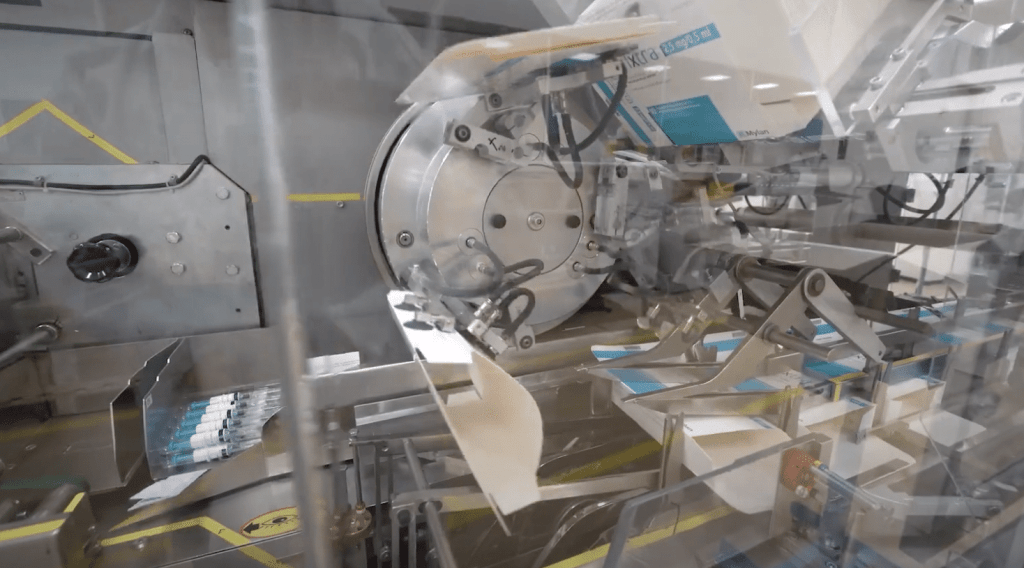

Aspen Pharma is a South African pharmaceutical company specializing in the manufacture of generic drugs. The group decided to expand into Europe following a transaction with GSK, with an accelerated growth in 2014 that led Aspen to set up operations in France, at their Notre-Dame-de-Bondeville facility, near Rouen. Today, Aspen Notre-Dame-de-Bondeville specializes in the manufacture of sterile products and has been working with fabriq for over a year to digitalize visual management and improve staff productivity.

750

employees at the Notre-Dame-de-Bondeville plant

+ 50

years’ experience in pre-filled syringes

400

million sterile units produced in 2023

More streamlined procedures for all short-interval meetings

Simplified communication and greater team involvement

Better responsiveness to problems

Issues encountered by Aspen Pharma staff at the Notre-Dame-de-Bondeville plant

Prior to the introduction of fabriq, managers at Aspen Notre-Dame-de-Bondeville had to collect information directly on the production lines and then manually record them on boards or paper. The data, taken from Excel files, was printed and this caused problems in terms of data entry and updates. In addition to these issues, Aspen Pharma staff also reported:

- A lack of standardization in the steering dashboards

- Loss and retention of information on issues, which stayed at shop floor level

- Time wasted through rekeying data

- A significant number of non-added-value tasks for operators and managers

- Excessive paper use

Introduction of fabriq to the Aspen Notre-Dame-de-Bondeville facility

fabriq is part of a plant-wide digitalization strategy, with the aim of eliminating non-value-added tasks, re-keying and data loss, as well as supporting staff in structuring problem-solving and performance monitoring processes. The solution was first implemented in the Visual Inspection (VI) and Packaging sections, on two pilot lines, before being deployed to the other lines, with the ultimate aim of deploying fabriq across the entire factory.

- Rollout of Fabriq at the Notre-Dame-de-Bondeville facility, in the Visual Inspection and Packaging sections

- Digitalization of rituals at 3 levels: operators, supervisors and managers.

- Creation of dashboards for monitoring performance indicators and managing action plans

- Development of problem-solving and the information escalation structure

How Aspen Pharma staff at Notre-Dame-de-Bondeville got to grips with the tool, and the benefits it provides

The staff at Aspen Notre-Dame-de-Bondeville got to grips with fabriq quickly and easily. The production manager implemented the tool little by little, starting with just a few indicators, so that the operators could gradually take ownership of the tool, before adding new indicators and new routines. But overall, the staff found the tool intuitive and quickly grasped the benefits. In particular, there has been greater involvement in performance management and feedback. Other reported benefits are:

- Time saved on weekly update meetings, which now only take 15 minutes

- Better responsiveness to problems

- Simplified communication and greater team involvement

- More streamlined procedures for all short-interval meetings

- Information history to speed up problems solving

- Consolidation of the continuous improvement approach, thanks in particular to cause analysis

- Better management of actions across the entire sector

- Improved overall productivity

“fabriq has phenomenal power. We can set up indicators for processing times, actions, gembas, problem-solving, etc. There are many tools we can use to consolidate our continuous improvement knowledge, and this improves our day-to-day operations.”

More feedbacks from our clients…

The testimonial of Scania

The testimonial of LVMH Fragrance Brands

The testimonial of Merck

🚀 Request a Demo Today!