The productivity of industrial companies depends on optimal management of processes and production lines. The aim of the 5S audit is to prevent any ‘grains of sand’ from getting into the working environment and to promote continuous improvement. As is often the case, we owe this method to a Japanese principle. Let us explain!

What is a 5S audit?

Among the different methods that can be implemented to improve organization in industry, 5S audits stand out as a strategy that is simple to implement, yet highly effective for reducing waste.

Definition of the 5S method

A 5S audit is about ridding the work environment of all unnecessary aspects that waste time, and organizing each tool so that it is used efficiently. The method is based on common sense and can be applied not only in an industrial environment, but in any type of business.

5S, 5 principles

The 5S principle was first introduced in Toyota factories. We all know how much the Japanese love everything to be done well and precisely. Take train punctuality, for example. And this includes carrying out factory audits.

To achieve this attention to detail in factories, companies apply the 5S method, which includes 5 precise principles (with Japanese terms that start with an S, even in translation!):

- Seiri or Sort: workstations are the first environments to be cleaned and sorted: this means highlighting the tools and objects that are used all the time, getting rid of those that are of no use (‘waste hunting’) and tidying away those that are used from time to time.

- Seiton or Set in order : “everything in its place”: when you know where something is, you don’t waste time looking for it. It’s important to position objects and, if necessary, label their ‘homes’.

- Seiso for Shine : the workstation must be spotlessly clean! Regular cleaning and frequent maintenance are essential to avoid being overwhelmed.

- Seiketsu for Standardize : this principle means putting methods into practice and sticking to them, scrupulously.

- Shitsuke for Sustain: for continuous improvement purposes, these same processes need to be monitored with dedicated tools.

What are the benefits of the 5S method?

The 5S method is a rigorous process that requires effort at the outset (especially if the work environment was messy). But if you stick to its principles, it will work without you even having to think about it.

Its benefits lie in its practical application in the field, which can then become a reflex in any situation. Once you’ve sorted and kept the important items, and cut out the clutter, you’ll save time.

5S is also a practical application of continuous improvement, based on a simple premise and a process audit.

The 5S principles create a model of efficiency and cooperation between colleagues, improving team spirit and employee engagement.

Last but not least, 5S audits help eliminate waste. And all this for a very modest implementation cost compared to a high-impact on performance and increased efficiency.

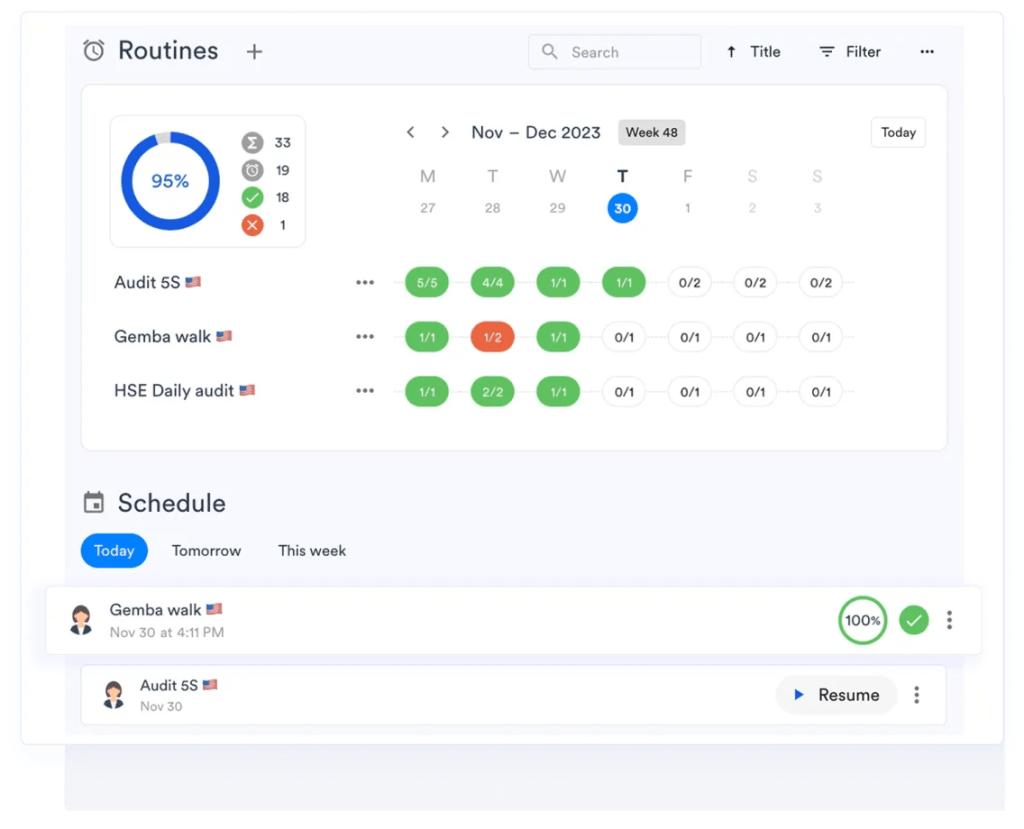

Example of scheduled routines in fabriq

Digitalizing 5S audits in practice

5S audits can be carried out on paper using 5S audit sheets or 5S audit checklists, but their performance will be greatly improved by a 5S audit digital solution that centralizes all the data and automatically issues key performance indicators (KPIs).

Fabriq, the digital 5S audit tool

With Fabriq’s help, you can digitalize your audits, SIM meetings and field tours, ensuring strict compliance with your norms and standards, while facilitating rapid problem detection. Your staff save time on a daily basis, and can draw on richer, more reliable data to find lasting solutions to problems.

- Create customizable, pertinent standards for collecting information directly from the shop floor.

- Plan sessions for your teams and monitor correct execution of your routines.

- Improve tracking and traceability in the event of non-compliance from standards during routines.

Follow these steps for a successful 5S audit!

For a successful 5S audit, a precise process needs to be followed, from the planning phase up front through to the execution of on-site field tours, including problem reporting and subsequent resolution.

To facilitate these steps, Fabriq now provides its clients with routine and checklist functionality, enabling them to carry out 5S audits with ease on a tablet or smartphone.

Step 1: Create, schedule and assign your audits and field tours

With a Daily Management System (DMS), you can create a custom checklist for each work area or manager. You can then schedule these over time, at the frequency you prefer, and assign them to the right people.

This gives you a clear overview of the checklists to be carried out and those who are responsible for audits receive automatic alerts.

How often should a 5S audit be carried out? 5S audits can take place on a monthly or quarterly basis, depending on the company’s needs. It is for the plant or section managers to decide. However, regular audits are recommended for optimal results.

Step 2: Do your audits and field tours on the move

Our fabriq mobile app gives audit managers even greater flexibility. They can do their rounds on the shop floor, and report non-conformities, even without a network connection.

Carrying out the audit involves creating a 5S audit checklist that is tailored to the working environment. This makes it possible to check that all the standards in place are working properly and effectively, making it easier to verify compliance or non-compliance.

Example of a 5S audit checklist in the fabriq app

Step 3: Detect and escalate problems

The audit manager can detect and escalate any problems, and enrich the data with photos and videos. This data provides valuable context for the problem, making it easier to solve. The manager can easily share this information and assign tickets to the relevant teams to ensure effective real-time problem- solving during the 5S audit.

And thanks to multi-device synchronization, there is no data duplication, simplifying the process. A digital signature then validates each inspection.

Step 4: Analyze your 5S audits

Thanks to the digitalization of your field tours, you can monitor compliance with your schedule and your process with audit completion rates via a dashboard. Analyze your data to improve your decision-making!