Regardless of the industry, competition is fierce in today’s market. To stay ahead, businesses must continuously find ways to optimize their systems and satisfy customer expectations. When you think you’ve already got a good product, the question arises – how do you find ways to improve? That’s where Kaizen comes in.

Kaizen is a Japanese term that first became popular in 1986. Ever since then it has been recognized as a key component of lean manufacturing. Read on to learn more about Kaizen and what are the 5 principles of Kaizen.

What is Kaizen?

Kaizen is derived from the Japanese words ‘Kai’ and ‘Zen’. Kai means change while Zen translates to good. Together, Kaizen means good change. It pushes businesses to continuously find ways to improve themselves by minimizing waste.

Kaizen applies to all processes within the organization as well as all its employees. Today, its principles have been adopted by manufacturing industries as well as governments, financial and healthcare service providers and even life coaches.

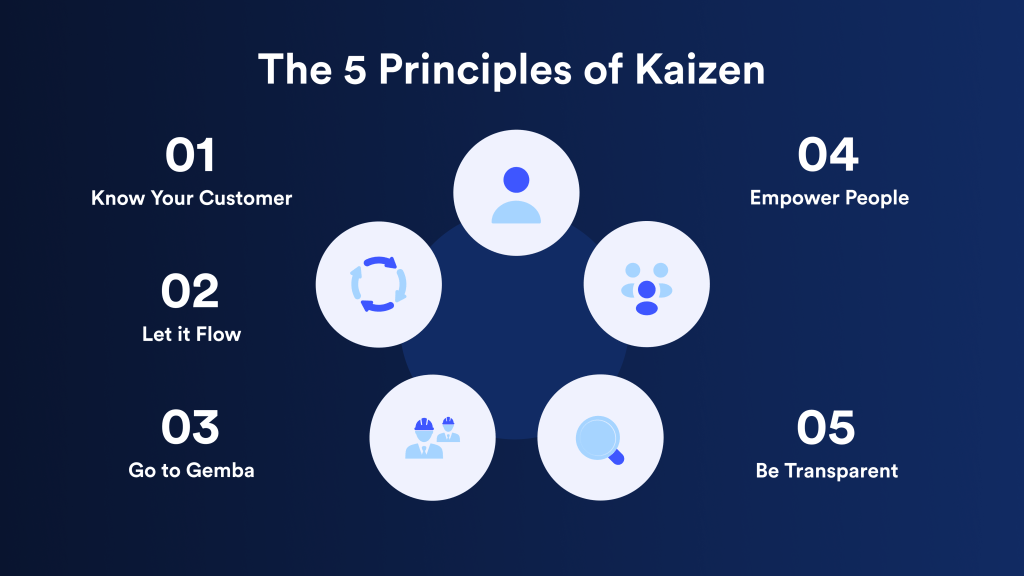

What are the 5 Principles of Kaizen?

Kaizen improvements can be big or small. It may be as simple as rearranging tools on a workstation. On a larger scale, it could involve adjustments by multiple departments to streamline processes. Either way, these changes are structured along 5 key principles. These are:

Principle 1: Know Your Customer

Customer loyalty is what every business strives to earn today. After all, even the most unique product can be reverse-engineered and fighting price wars are futile. To win a customer’s loyalty, you need to deliver exceptional service that’s personalized to their needs. For this, you need to know your customer.

The first Kaizen principle focuses on understanding customer needs, interests and expectations. Asking customers for feedback, reviews and suggestions is a good way to start. This is the first step to identifying where you need to make changes to increase value.

Principle 2: Let it Flow

Kaizen focuses on increasing value by minimizing waste. This refers not only to waste generated while manufacturing products but anything that does not add value to the customer’s experience. Zero waste is the ultimate target, even if it seems unattainable.

This principle also indicates that processes must flow continuously. You do not need to stop everything to implement changes. Rather, make small changes along the way that help reduce waste.

For example, you may choose to order raw materials in smaller quantities to reduce inventory. Or you might automate repetitive tasks to shorten the production cycle.

Principle 3: Go to Gemba

When translated from Japanese, Gemba means ‘the real place’. ‘Go to Gemba’ directs decision-makers and leaders to be physically present at varied operational stages. This gives them first-hand information on what is happening in all departments and a chance to engage with employees directly.

Regular Gemba walks help leaders identify opportunities for improvement and encourage employees to participate in the process. Real-time observations can trigger quick improvements that streamline the process and prevent delays. It’s a great morale booster too!

Principle 4: Empower People

Kaizen does not limit the responsibility for change to the top management. It encourages active participation by employees at all levels. This Kaizen principle is directed towards developing systems and tools as well as setting goals that empower employees. Let workers take charge of their tasks and workstations while working towards a common goal. This ensures that everyone’s efforts are aligned with each other.

The principle of empowering people with Kaizen isn’t just about giving employees the chance to report issues but also actively involving them in the solution-finding process. For example, you could include workers from different departments in a brainstorming session.

Principle 5: Be Transparent

Simply making a change is not enough. You must be able to measure its impact. Measuring progress shows you where you can improve further.

Making these metrics accessible to a wider audience and sharing them has additional benefits. It builds trust in the system and encourages the team to continue working towards a culture of continuous improvement.

Benefits of Applying Kaizen Principles

Applying Kaizen principles has many benefits. Key amongst them are:

- Stronger collaboration

Kaizen encourages everyone in an organization to take responsibility for improving systems. It encourages teamwork and collaboration between people on the same team as well as in different departments. Further, solving problems as a team strengthens the bond between employees and helps each one gain a new perspective.

- Increased efficiency

Kaizen focuses on reducing waste in all forms to maximize value. This includes wasted materials, time, resources, etc. Keeping this in mind, Kaizen improvements aim at simplifying processes and removing any unnecessary steps or processes along the way. Doing this boosts efficiency and minimizes the risk of potential errors.

- Higher employee satisfaction

By listening to workers during Gemba walks, empowering employees to take charge of systems and streamlining their workflow, Kaizen benefits employers and employees.

Employees feel valued for their expertise and are happier in the workspace. In turn, this earns their loyalty and reduces the churn rate. What’s more, by giving them a voice to pitch improvements, Kaizen makes employees advocate for itself.

- Safer workspace

Accidents not only put an employee at risk of injury but could also create bottlenecks in the system and hamper the workflow. Hence, safety is an important concern when making any change.

For example, a small change like rearranging workstations saves time and minimizes employee movement and material transportation. In turn, this reduces the risk of accidents on the shop floor.

How to Implement the 5 Principles of Kaizen

Every organization will have a different perspective on implementing Kaizen principles. Ideally, it should involve employees at all levels of hierarchy. Here are a few ideas to get you started.

- Install a suggestion box

Even with Gemba walks, not all employees may be confident enough to share ideas and suggestions. A suggestion box allows these employees to voice their concerns and share suggestions in a way that is comfortable for them.

- Focus on small changes

Rather than try to redesign the wheel, focus on small changes. These changes are easier to execute and less likely to face resistance.

- Encourage experimentation

Encourage employees and decision-makers at varying levels to experiment with changes to an existing system. Implement these changes on pilot projects to test them. If they are successful, they can be implemented across the system. Else, you can try something different.

- Standardize successful changes

When you see a small change make a positive impact on your efficiency and productivity, standardize its implementation across all departments. Each small change standardized in this way will improve the overall process.

In conclusion, communication is key to successfully implementing Kaizen principles in any industry. This is where a digital solution like fabriq can help. The graphic representation of key performance metrics and standardized workflows makes it easy to spot opportunities for improvement, share ideas, track progress for pilot projects and standardize success stories.

In short, it supports all Kaizen principles and fosters a culture of continuous improvement. Beyond everyday continuous improvement, many organizations also run Kaizen events which are structured, short-term improvement workshops that rapidly solve specific problems.

Want to know more – reach out for a demo.

5 Principles of Kaizen: FAQ

What is Kaizen?

Kaizen is derived from the Japanese words ‘Kai’ and ‘Zen’. Kai means change while Zen translates to good. Together, Kaizen means good change. It pushes businesses to continuously find ways to improve themselves by minimizing waste.

What are the 5 Principles of Kaizen?

The 5 principles of Kaizen are:

1. Know Your Customer

2. Let it Flow

3. Go to Gemba

4. Empower People

5. Be Transparent

What are the benefits of applying Kaizen Principles in the factory?

4 of the main benefits of Kaizen are stronger collaboration, increased efficiency, higher employee satisfaction, and a safer workspace.

How can I implement the 5 principles of Kaizen?

Here are a few ideas to get you started with Kaizen: install a suggestion box, focus on small changes, encourage experimentation, and standardize successful changes.