A Kaizen event is a short-term, focused initiative where cross-functional teams work together to solve a specific problem or improve a process on the manufacturing shop floor. Based on the Japanese idea of continuous improvement, called kaizen, these events usually last three to five days. They aim to create quick results by empowering employees to identify inefficiencies and implement changes.

These rapid improvement workshops help teams reduce waste, improve quality control, and shorten lead times across critical business processes.

Kaizen itself is rooted in five foundational principles which also guide how Kaizen events are structured and executed.

What Is a Kaizen Event in Manufacturing?

In a lean manufacturing environment, Kaizen events are a powerful improvement tool to reduce waste, streamline workflows, and improve productivity. A kaizen event is different from daily incremental improvements. Kaizen events are more intensive, with dedicated time, people, and resources devoted to a targeted issue. It’s a cornerstone of lean kaizen methodology and a proven driver of shop floor problem solving.

Kaizen events are also known as “Kaizen blitzes” or “rapid improvement events.” In other words, these terms highlight their fast-paced and solution-driven nature. Kaizen events often use lean tools like value stream mapping, root cause analysis, spaghetti diagrams, and the PDCA cycle. These tools help identify and solve problems effectively.

When and Why to Run a Kaizen Event

A Kaizen event is most effective when there is a clearly defined problem or opportunity for improvement that can be addressed within a short time frame. This could involve improving quality control, reducing lead times, or removing inefficiencies in core manufacturing processes. Common triggers or scenarios for organizing a Kaizen event include:

- Recurrent quality control issues or production defects

- Bottlenecks slowing down throughput and increasing lead times

- Excessive material handling or waste (motion, inventory, overproduction)

- Safety concerns or ergonomic issues

- Layout inefficiencies or long setup/changeover times

Kaizen events align teams around shared goals and accelerate progress toward continuous improvement. For shop floor managers, they offer a structured way to tap into frontline expertise. For operational excellence leaders, Kaizen events are a repeatable method for embedding lean manufacturing principles in everyday work.

These events also act as effective training experiences. Participants build their problem-solving skills, learn to apply lean tools, and take ownership of the solutions they develop. Over time, Kaizen events can catalyze a lasting shift toward a culture of continuous improvement.

8 Steps to Run a Successful Kaizen Event

Running a successful Kaizen event requires planning, collaboration, and follow-through. Here are the key steps:

1. Identify the Problem and Define Objectives

First, start with a clear problem statement and measurable goals. What manufacturing process needs improvement? What outcomes do you want to achieve? Define the scope of the Kaizen event to ensure it remains manageable and focused.

2. Select the Right Team

Assemble a cross-functional team that includes shopfloor operators, supervisors, engineers, maintenance staff, and quality professionals. Involve people closest to the work to establish practical insights, encourage ownership and ensure buy-in.

3. Prepare for the Event

Before the event begins, gather relevant data such as KPIs, production logs, and defect rates. Share the event schedule and communicate expectations. Offer training in important lean tools like 5S, root cause analysis, and visual management.

4. Map the Current State

Use visual tools like value stream mapping or spaghetti diagrams to visualize and analyze the existing workflow. Look for signs of waste, variation, or inefficiency that could be contributing to the problem.

5. Analyze Root Causes

Facilitate brainstorming sessions to uncover the root causes of the identified problems. Use lean problem solving tools, for example the 5 Whys or fishbone diagrams, to go deeper and ensure the team addresses the right issues.

6. Develop and Implement Solutions

Work together to design new processes or improvements. The pilot changes quickly to test if things work. This includes rearranging workstations, updating standard operating procedures (SOPs), or adding new tools.

7. Measure Results and Standardize

Finally, at the end of the Kaizen event, compare outcomes to your original goals. Did you reduce defects and improve cycle time? Did you save floor space or improve quality? Document the new standards and ensure everyone is trained to maintain the improvements.

8. Follow Up

Lastly, assign owners for follow-up tasks and plan for periodic audits. Sustainable improvement comes from long-term commitment, not just the event itself. Regular audits and feedback loops help prevent backsliding.

Best Practices to Lead a Kaizen Event on the Shopfloor

Leading a Kaizen event requires both structure and flexibility. Here are best practices to maximize success:

Engage the shopfloor early. Operators and frontline workers are experts in the process. Involve them in defining problems and shaping solutions.

Keep the scope focused. Trying to fix everything at once leads to burnout and confusion. Choose a defined area or process.

Use visual tools. Visual management boards, floor tape, and digital dashboards make it easier to communicate goals, progress, and results.

Celebrate small wins. Recognize the team’s contributions and share results across the factory to build momentum.

Ensure management support. Leaders should remove roadblocks and champion the team’s efforts during and after the event.

Focus on sustaining. The hardest part of a Kaizen event isn’t the implementation, it’s keeping the changes in place. Use audits, standard work, and follow-ups to embed improvements.

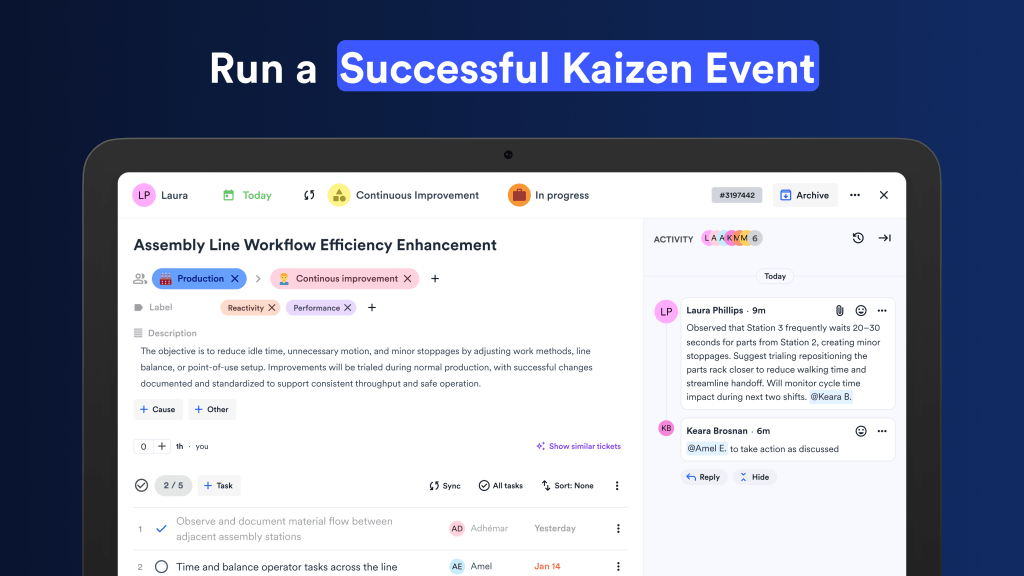

How Digital Tools Enhance Kaizen Events

While Kaizen events have traditionally relied on paper-based tools, digital platforms are increasingly important. When teams use digital solutions, Kaizen events become more effective and sustainable. Teams can use digital tools to document actions, track performance, and collaborate in real time.

A digital Kaizen event management system can:

- Centralize data collection and visualization

- Provide real-time performance dashboards

- Facilitate cross-functional communication

- Automate reminders for follow-up tasks

- Ensure traceability of actions and results

Digital tools help leaders find patterns in different events. They also help prioritize areas for future improvement. Additionally, these tools allow leaders to replicate successful outcomes in other teams or locations.

In short, digital tools don’t replace people, they empower them. By combining lean kaizen principles with modern technology, manufacturers can unlock faster, more sustainable gains in efficiency and quality.

Kaizen Events Drive Continuous Improvement in Manufacturing

Kaizen events are one of the most effective tools in a manufacturer’s continuous improvement toolbox. They empower shop floor teams to solve problems rapidly, eliminate waste, and enhance performance. More importantly, they foster a culture of accountability, engagement, and innovation.

When supported by the right digital tools, Kaizen events become even more powerful. Teams can act faster, track impact more precisely, and sustain gains over the long term. Investing in Kaizen events, and the systems that support them, is a smart move toward operational excellence. Especially for manufacturers serious about lean manufacturing and shop floor problem solving.

Want to see Kaizen principles in action? Discover how Bel boosted continuous improvement, saved time and empowered teams with fabriq.

Request a demo to see how fabriq helps manufacturers run more effective Kaizen events. Discover how you can digitize workflows, track impact in real time, and ensure long-term follow-up, right on your shop floor.